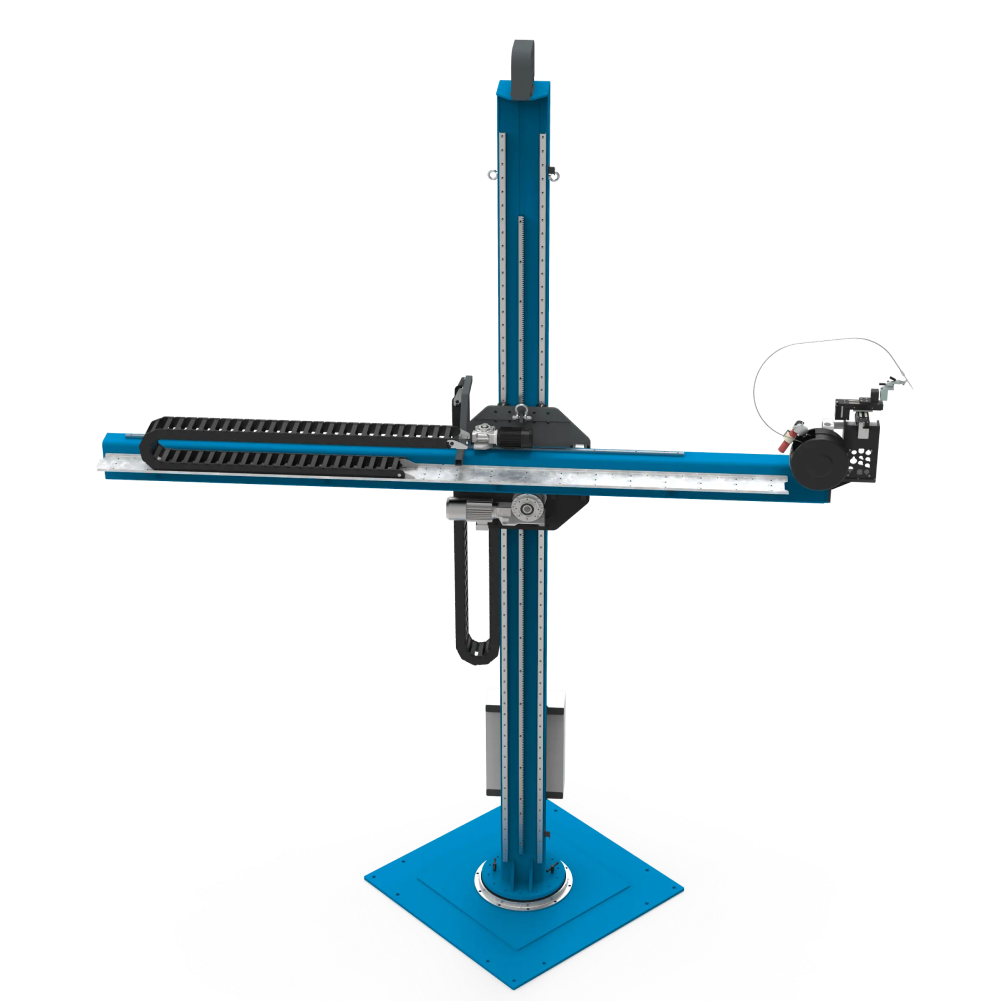

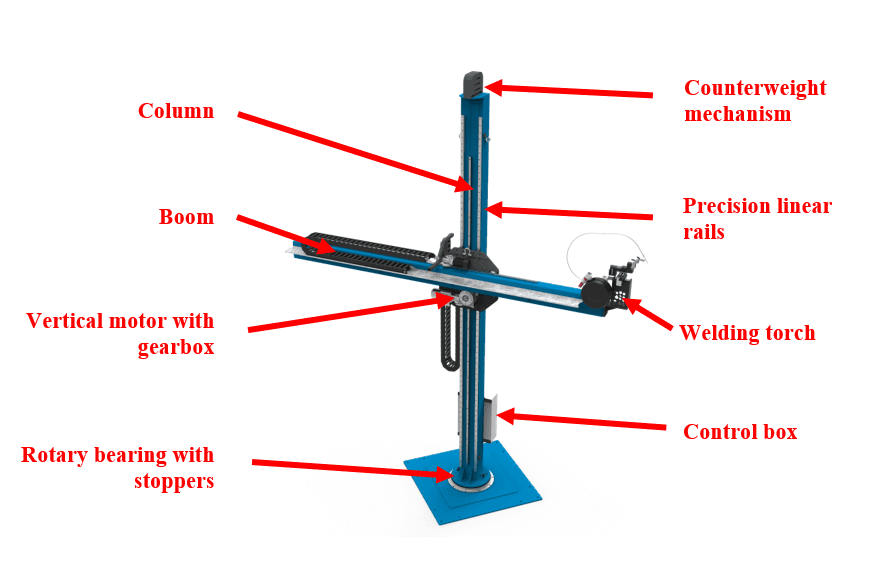

Our column and boom welding machines KVS now have a new variant — the KVS-H. Upon customer request, we developed a custom console machine for plasma welding of large pipes. This simplified version features two-axis movement without additional cross slides and manual column rotation. A complete plasma welding system is mounted on the boom.

One of the unique aspects of this version is the vertical movement along the Z-axis, driven by a rack and pinion system, rather than a spindle system as used in the KVS-L model. This allows for greater vertical travel, making it possible to weld larger pipes. In this case, we produced a machine with a 4-meter vertical stroke and a 3-meter horizontal stroke.

Both axes are precisely repeatable and accurate, thanks to linear guides and ball bearings. The travel speed of both axes is adjustable to meet customer requirements. This is especially important for welding processes that require continuous movement of the boom during welding.

We also developed a wired remote control to make the machine setup easier. Using the remote, the operator can position the boom precisely before welding and adjust the torch position for the desired weld.

Key Features of the KVS-H Machine:

- Two-axis motorized movement for welding

- Manual column rotation using a high-quality bearing

- Remote control for speed and direction adjustment

- Speed settings before and during welding

All cables, hoses, and torch packages are protected within cable chains for neat and secure routing. The KVS-H has a fixed base plate that must be anchored to the floor with bolts. The base plate includes a bearing system that allows the column to rotate, with rotation being locked using special tightening clamps. The machine is powered by a standard 230V plug connection for easy installation.