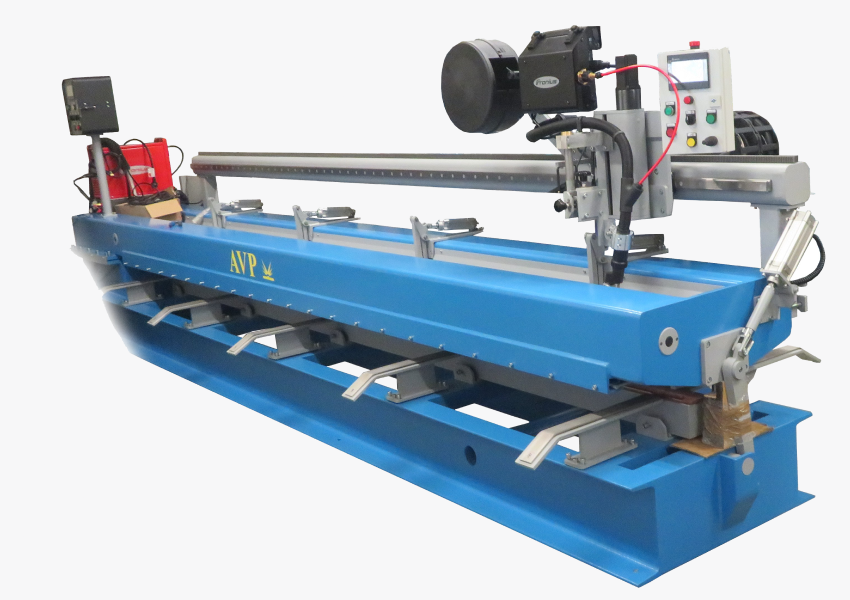

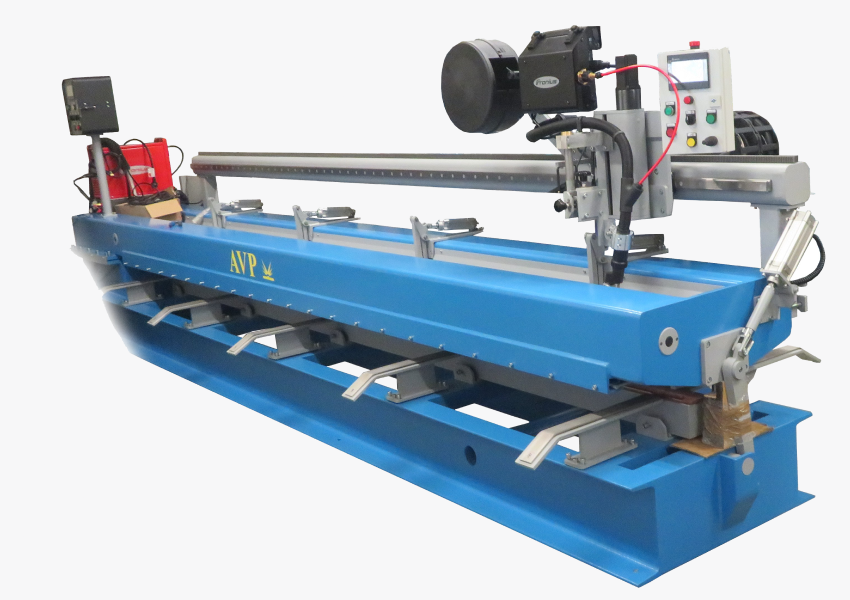

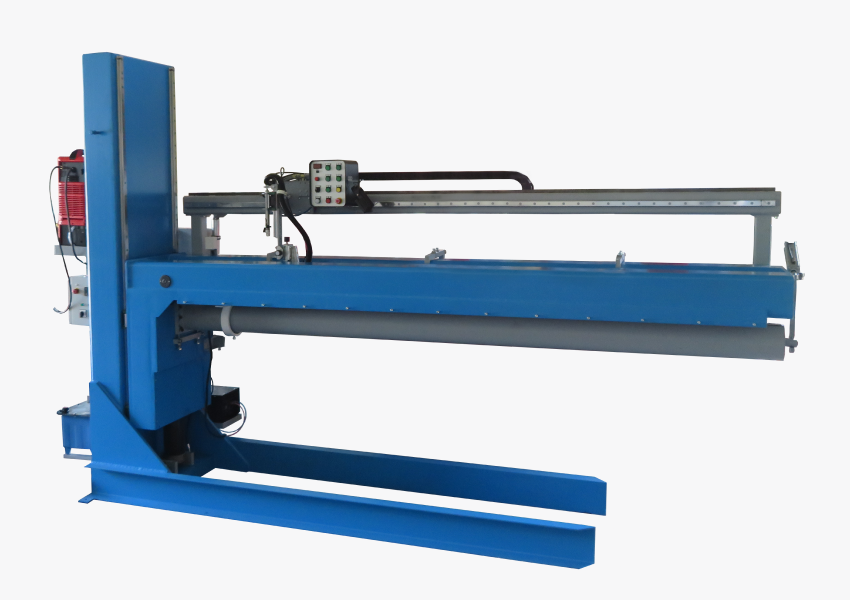

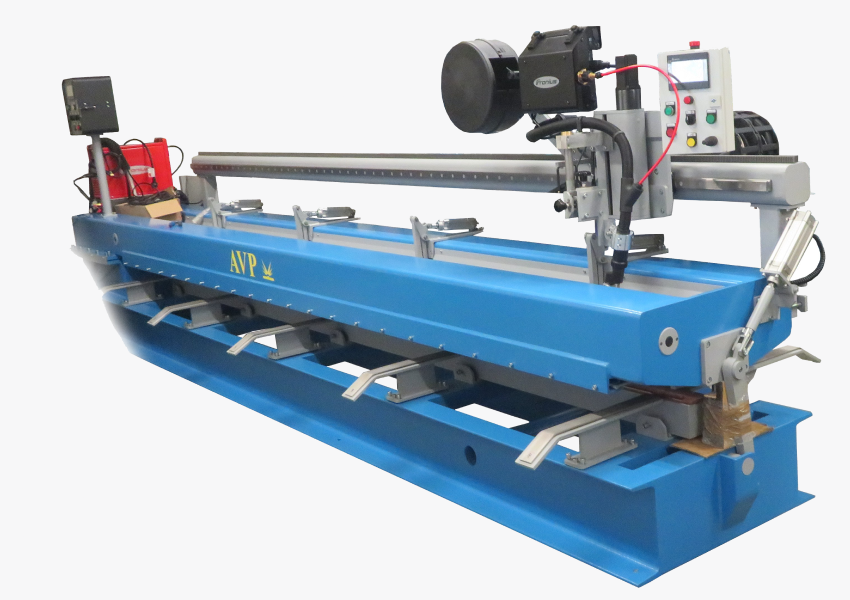

Automatic machines for longitudinal seam welding enable highest quality welding of sheets and pipes with thicknesses from 0.5 mm without prior spot welding. They are used for welding plates, pipes, boxes, cones, and various materials using TIG, MIG/MAG, laser, plasma, and EPP welding processes. Longitudinal seam welding machines mainly consist of a base frame, copper clamps, centering devices, water cooled backing bar, guide rail with support, and torch adjustment elements. The AVP centering device ensures quick and accurate zero-gap clamping. The mandrel has a water-cooled backing rail with gas underflow. Torch elements allow adjustment to the desired position (3-axis adjustment) and correction of the position during the welding process. Control and parameter storage is enabled via a touch screen.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

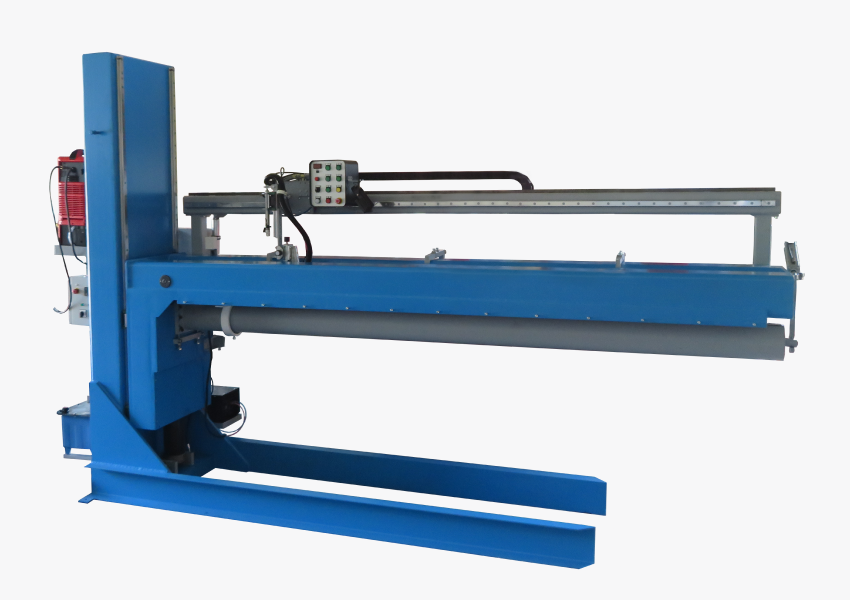

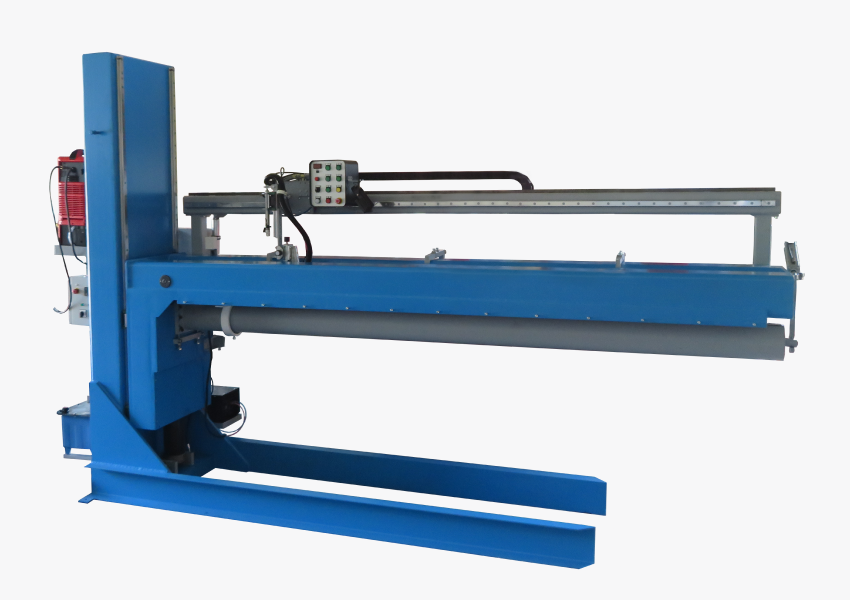

This type is used for outside seam welding with an option for inside welding. The hydraulic lift improves the work process and allows ergonomic work regardless of the weldment size (pipe).

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Stay in touch with us and follow our latest solutions for automatic welding

Stay in touch with us and follow our

latest solutions for automatic welding

Welding Automation

Welding Machines

© 2025 | AVP Welding Automation | All rights reserved