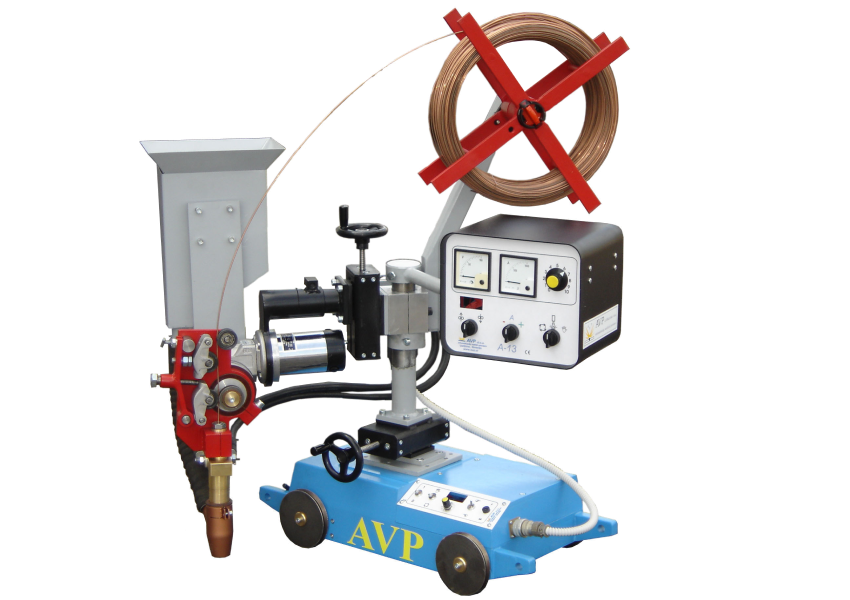

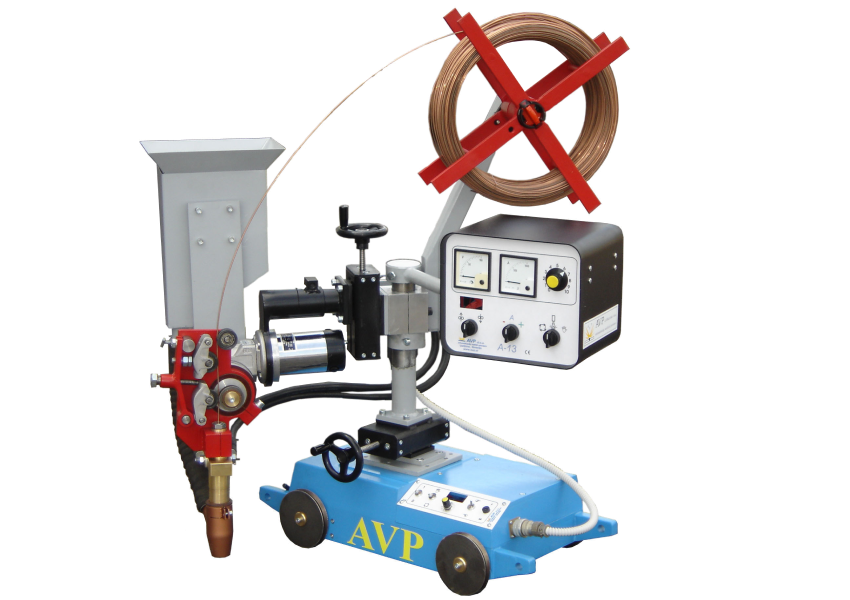

The A13 is used for fast, economical, high quality welding, and for welding structural plates, alloy plates or profiles. It provides the cheapest and most productive welding process for thick plate – up to 300x faster compared to REL (MMA). The A13 is a universal machine consisting of three main units: the carriage, the EPP head and the EPP control box.

The carriage is used for the longitudinal feed of the A13, as a stand-alone unit with its own drive and continuous speed control. The speed is adjustable from 0,2 to 2,0 m/min. The A13 welding head is mounted on robust sleds which allow very precise feed in both horizontal and vertical directions. The welding head can also be a stand-alone unit to be retrofitted to other types of stationary and mobile machines. The head can be tilted in two directions so that welding can be carried out in any position. Changing the contact nozzles is easy. The powder hopper is positioned just above the welding head to ensure a constant supply of powder. The control box is universal, allowing the use of all types of sources and allowing the selection of welding current with a straight or downward characteristic.